Quality

Quality starts with a good design that takes into account all prevailing regulations and standards.

SPECIALIZED SOFTWARE

- We master the most internationally renowned construction codes: AD2000, EN 13.445, ASME VIII Div. I, EN14.015, API 650.

- Our CAD software is directly linked to our production machines, reducing to a minimum any errors caused by copying, redrawing and/or reworking.

- A high-performance ERP system links all materials to the right projects, identifiable throughout the entire production process.

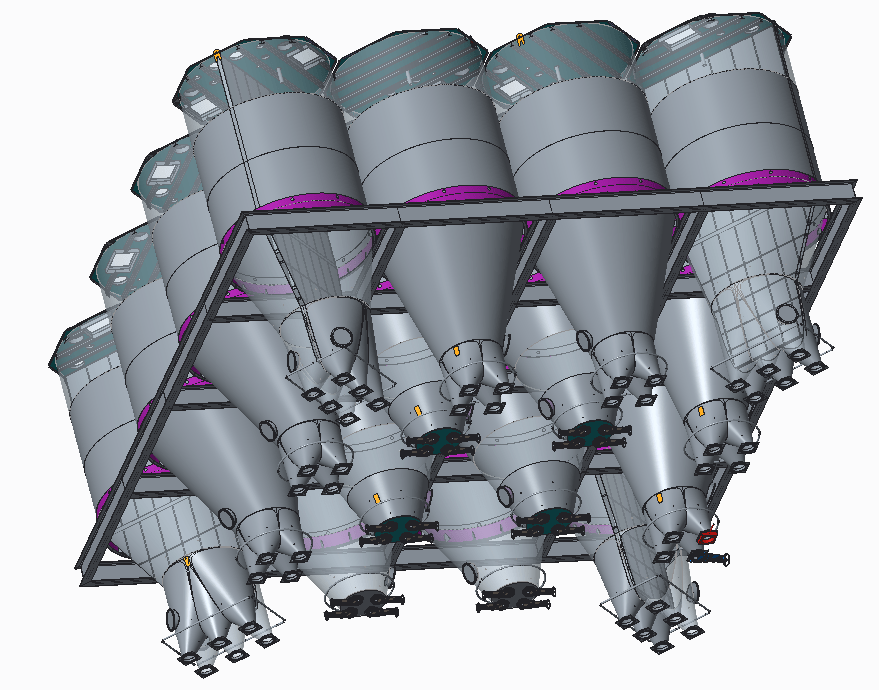

3D MODELLING

- 3D modelling is used to simulate and calculate all possible loads.

- These results are then translated into a detailed construction drawing (3D or 2D) that is submitted for approval to the client prior to the START of any project.

CERTIFICATION

- All our welders are EN-ISO 9606-1 certified, and receive regular follow-up and approval from the inspection bodies. Welding is done according to EN-ISO 1561:2004-certified welding procedures using the most diverse materials, from regular steel to high-alloyed stainless steel types.

- Knowing by Measuring. Prior to painting and/or finishing, each project is carefully inspected in accordance with our drawings. Deviations are recorded and tested using the prevailing standards for tolerances.